News

more+- Professor Chen Erfan, a leader of our company, was invited to attend the inauguration ceremony for the new location of Shenyang Zhilang Technology Co., Ltd. and visited its research achievements and new products.

- The 4th Annual Meeting of the Special Committee and the 3rd New Materials Science & Technology Conference Held in Hangzhou

- Professor Chen, a leader of our company, participated in the Standardization Technical Committee of the Chemical Industry and Engineering Society of China.

- Warm Congratulations on Our Company Being Awarded the Certificate of High-Tech Enterprise!

- Chairman Chen Erfan Participated in Liaoning International Rubber Technology Exchange Festival as a Specially Invited Expert.

contact

more+Contact Phone:13147811246 13147811216

Landline:13147811246 13147811216

Corporate Email:tech@rdpmcn.com

Address:Hongfa International, Shenliao Road, Tiexi District, Shenyang City, Liaoning Province, P.R.China

Sales Phone:13147811246 13147811216

Recycled Resin Mold Materials

Release Date:2026-01-13

Page Views:108

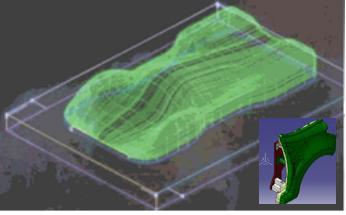

Recyclable resin mold materials can shorten the production time of models and molds, reduce the production costs of models and molds, and improve the processing accuracy of models and molds. Moreover, they have promoted the rapid development of the model and mold industry.

There are mainly two categories: epoxy resin and polyurethane mold materials. They are characterized by high dimensional stability, rigidity, impact toughness, hardness, as well as good processing performance, heat resistance, surface properties, and corrosion resistance. They are relatively light in weight, convenient for manufacturing, modification, or repair, and can be processed faster at a lower cost. This not only shortens the mold production time and reduces the mold production cost but also improves the mold processing accuracy.

They can be widely used in aerospace, machinery, automobiles, home appliances, rubber and plastic processing, and civil fields. For example, they are used in aircraft sheet metal part tooling molds, new car model production, automotive part inspection fixture manufacturing, tire mold base mold manufacturing, wind turbine blade manufacturing for wind power generation, sole base mold manufacturing in the footwear industry, trial - cutting materials for high - precision parts, and high - precision ship model manufacturing.

However, since resin molds are thermosetting polymer materials (network - structured), the discarded scraps or waste molds cannot be disposed of, causing significant environmental pollution and resource waste at the same time.

Our company has developed a preparation technology and products of a recyclable epoxy - polyurethane semi - interpenetrating network resin (EPU semi - IPNs) mold material using epoxy resin or polyurethane mold material scraps or waste molds as raw materials.

Comparison of technical characteristics

Technical performance | international AXSON | international HUNTSMAN | Project products (adjustable) |

density(23℃),g/cm3 | 0.65~1.8 | 1.0~1.7 | 0.6~1.8 |

hardness,SHORE D1 | 63~90 | 85~90 | 63~90 |

Flexural strength,MPa | 34~70 | 60~70 | 35~100 |

Flexural modulus of elasticity,MPa | 1000~4000 | ~4500 | 1000~4000 |

Compressive strength,MPa | 28~80 | 80~90 | 28~120 |

Impact strength,KJ/m2 | 11~55 | 25~58 | 11~58 |

HDT/℃ | 50~55 | 50~65 | 50~90 |

(CTE)[+10;+60]℃,10-6.K-1 | 75 | 45 | 32~40 |