News

more+- Professor Chen Erfan, a leader of our company, was invited to attend the inauguration ceremony for the new location of Shenyang Zhilang Technology Co., Ltd. and visited its research achievements and new products.

- The 4th Annual Meeting of the Special Committee and the 3rd New Materials Science & Technology Conference Held in Hangzhou

- Professor Chen, a leader of our company, participated in the Standardization Technical Committee of the Chemical Industry and Engineering Society of China.

- Warm Congratulations on Our Company Being Awarded the Certificate of High-Tech Enterprise!

- Chairman Chen Erfan Participated in Liaoning International Rubber Technology Exchange Festival as a Specially Invited Expert.

contact

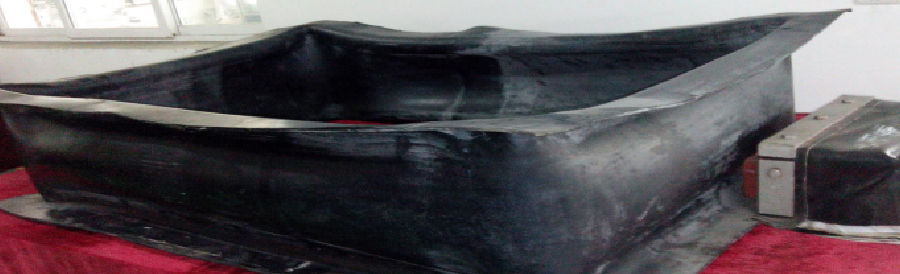

more+Rubber Coated Fabre with High Temperature Resistance and Anticorrosion Rubber

The desulfurization device (non-metallic compensator) is used to solve the thermal expansion caused by industrial flue gas during transmission, provide large multi-directional compensation, and eliminate installation cumulative errors.

In addition to SO₂, coal combustion also produces small amounts of gases such as SO₃, NOₓ, HCl, and HF, which form highly corrosive solutions such as H₂SO₄, HCl, and HF with moisture in the flue gas.

The inlet flue gas temperature of the absorption tower can reach up to 180℃, while the inner cavity is long-term exposed to a humid and hot environment of 45–70℃ with alternating acid and alkali conditions.

It can be seen that the wet dust removal and desulfurization system operates in a harsh environment with strong corrosive media, humid heat, and high abrasion.

Due to the severe corrosive environment, the desulfurization system has extremely strict requirements for material corrosion resistance, wear resistance, and temperature resistance. Therefore, material performance has a great impact on the service life and cost of the system, and is regarded as one of the key technologies in the design and manufacture of flue gas desulfurization devices.

The high-strength anti-corrosion rubber fabrics used are mainly glass fiber fluororubber fabric and EPDM-coated glass fiber fabric.

Among them, fluororubber-coated glass fiber fabric can withstand long-term service temperature up to 250℃, but is expensive; the long-term service temperature of EPDM rubber fabric is 120℃.

The new high-strength anti-corrosion rubber fabric developed by our company has a long-term service temperature of 180℃.

Its other properties can fully meet the requirements of the working environment of glass fiber fluororubber fab

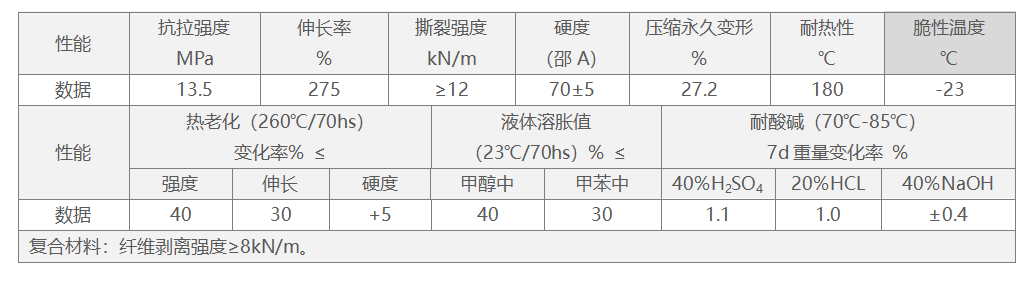

Main Performance and Technical Indicators

|

|

| |