News

more+- Professor Chen Erfan, a leader of our company, was invited to attend the inauguration ceremony for the new location of Shenyang Zhilang Technology Co., Ltd. and visited its research achievements and new products.

- The 4th Annual Meeting of the Special Committee and the 3rd New Materials Science & Technology Conference Held in Hangzhou

- Professor Chen, a leader of our company, participated in the Standardization Technical Committee of the Chemical Industry and Engineering Society of China.

- Warm Congratulations on Our Company Being Awarded the Certificate of High-Tech Enterprise!

- Chairman Chen Erfan Participated in Liaoning International Rubber Technology Exchange Festival as a Specially Invited Expert.

contact

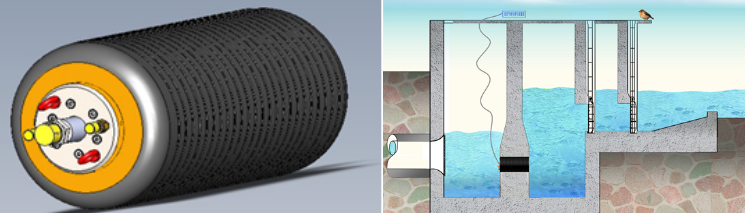

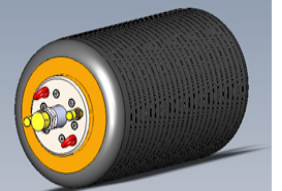

more+Plugging airbag/Inflatable pipe plugs

★ Main Features & Technical Specifications:

Main material: EPDM; inner core: butyl rubber.

Service life: more than 50 years.

Eco-friendly & food-grade hygienic standard.

Air/water tightness: maintains working pressure for 1 year without leakage.

Safety & reliability: waterproofing and pressure relief functions unaffected under Magnitude 7 earthquake; working pressure: 1.2 MPa; automatic pressure relief via magnetic valve in emergency.

Friction coefficient / skid resistance: dry 0.5~0.8, wet 0.25~0.75.

Easy operation: deflation time < 30 seconds; floats up naturally without obstruction or blockage.

★ Adopted Standards::

Service Life Evaluation: ISO 11346:1997 Rubber, vulcanized or thermplastic — Estimation of lifetime and maximum temperature of use from an Arrhenius plot

Food Hygiene Test: GB 4806.1-1994 Hygienic Standard for Rubber Products for Food Use

Air Tightness Test: GB/T 11194-2004 Test Method for Air Tightness of Aircraft Tubeless Tires

Working and Bursting Pressure: ISO 1402:2009 Rubber and plastics hoses and hose assemblies — Hydrostatic testing

Friction Coefficient Test: HG/T 2729-1995 Rubber, vulcanized — Determination of friction coefficient of thin sheets — Sliding method

Mechanical Properties of Materials: ISO 37:2005 Rubber, vulcanized or thermplastic — Determination of tensile stress-strain properties

Aging Resistance: ASTM D 518:1999 Standard Test Method for Rubber Deterioration — Surface Cracking