News

more+- Professor Chen Erfan, a leader of our company, was invited to attend the inauguration ceremony for the new location of Shenyang Zhilang Technology Co., Ltd. and visited its research achievements and new products.

- The 4th Annual Meeting of the Special Committee and the 3rd New Materials Science & Technology Conference Held in Hangzhou

- Professor Chen, a leader of our company, participated in the Standardization Technical Committee of the Chemical Industry and Engineering Society of China.

- Warm Congratulations on Our Company Being Awarded the Certificate of High-Tech Enterprise!

- Chairman Chen Erfan Participated in Liaoning International Rubber Technology Exchange Festival as a Specially Invited Expert.

contact

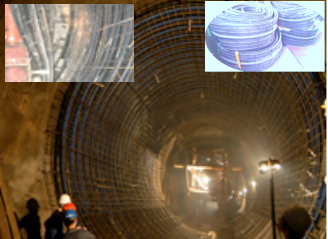

more+Elastic Water Stop with High Performance

The water stop belt is a strip - shaped material used to prevent water seepage. It is widely applied to construction joints, deformation joints, settlement joints, post - cast strips, or areas where pipes pass through walls (slabs) in waterproof parts of civil engineering projects such as water conservancy, tunnels, subways, and municipal works.

Our company has developed high - performance food - hygiene - grade long - life rubber materials and water stop belts through optimized design of the raw rubber system, reinforcement system, cross - linking system, etc. All technical indicators far exceed the requirements of relevant national standards, and can meet the stringent requirements of large - scale water conveyance projects. This technology and product have been granted one invention patent and one utility model patent respectively, and have won the Second Prize of Science and Technology Progress of Sinopec and Liaoning Province respectively. They have been successfully applied to large - scale water conservancy projects such as the Dahuofang Water Conveyance Project.

Main performance characteristics

Long lifespan: The developed material has undergone hot - air accelerated aging tests for as long as three years. According to the international standard ISO 11346:1997, the service life of the material at normal temperature exceeds 100 years.

"Green": The food hygiene technical indicators are four orders of magnitude higher than the national standard GB4806.1 - 94 "Hygienic Standard for Rubber Products Used in Food".

High strength: The tensile and tear strength of the water stop belt and its material reach 18MPa and 50/kN/m respectively. With the addition of transverse ribs, the deformation is reduced by 32.07%, and the stress resistance to deformation is increased by 40.17%. The strength is much higher than that of common rubber water stop belts, and one copper water stop belt can be omitted.

Large deformation: The ingenious shape design of the water stop belt - a temporary sealing opening, can adapt to large stress and deformation. Before and during construction, it can prevent debris, water, etc. from entering the central hole. After being torn naturally or artificially, it can timely discharge the debris or water that has entered the central hole, reducing the risk of water stop belt failure. Under large stress, it will naturally tear into a wave - like shape, adapt to large deformation, and still maintain the water - stopping function.

Effective interlocking with surrounding concrete: While adding transverse ribs and ribs, the size ratio of the transverse ribs and ribs is made reasonable, which greatly enhances the effective interlocking between the water stop belt and the surrounding concrete and its fixation during construction, preventing detachment and achieving better waterproof and water - stopping effects.

Improved constructability: The rigidity of the water stop belt is increased and its shape is stable, which facilitates effective positioning and fixation during construction. The process of using steel bars for positioning and fixation during construction can be omitted. The annular structure reduces the process of forming a loop on - site for common rubber water stop belts, and at the same time ensures the overall quality of the water stop belt (the strength at the joint of on - site loop formation is only 0.5 - 0.7 of that of the belt body).

| ||

| water stop belt | construction site | Cut the ribbon for the project |