News

more+- Professor Chen Erfan, a leader of our company, was invited to attend the inauguration ceremony for the new location of Shenyang Zhilang Technology Co., Ltd. and visited its research achievements and new products.

- The 4th Annual Meeting of the Special Committee and the 3rd New Materials Science & Technology Conference Held in Hangzhou

- Professor Chen, a leader of our company, participated in the Standardization Technical Committee of the Chemical Industry and Engineering Society of China.

- Warm Congratulations on Our Company Being Awarded the Certificate of High-Tech Enterprise!

- Chairman Chen Erfan Participated in Liaoning International Rubber Technology Exchange Festival as a Specially Invited Expert.

contact

more+Contact Phone:13147811246 13147811216

Landline:13147811246 13147811216

Corporate Email:tech@rdpmcn.com

Address:Hongfa International, Shenliao Road, Tiexi District, Shenyang City, Liaoning Province, P.R.China

Sales Phone:13147811246 13147811216

Anti-Scratch, Stable-Proof, High-Wear Rubber Materials, Oil Pipelines and Dredging Pipe

Release Date:2026-01-13

Page Views:74

Dredging rubber hoses are supporting products for dredging construction ships and dredgers, and are used in projects such as sediment removal and sewage discharge in rivers, lakes and seas, waterway dredging, port construction, land reclamation from the sea, and seabed mining. Marine oil transportation rubber hoses are used for the transportation of oil and oil substances between oil tankers, between oil tankers and drilling platforms, and between oil tankers and docks.

Due to the factors of the working medium of stone and sand and the high-impact working conditions, the inner linings of dredging and marine oil transportation rubber hoses are severely damaged and worn, reducing their service life. Recently, some enterprises have adopted the method of pasting ceramic linings, hoping to improve the wear resistance of dredging hoses and reduce energy consumption during the construction process. However, after actual use, some ceramic tiles fell off, cracked, and showed obvious wear, affecting their flexibility.

Our company has developed an anti-scratch, anti-puncture, and highly wear-resistant rubber material. The oil transportation hoses and dredging hoses manufactured with this material fully meet the specifications of HG/T 2490 - 2011 Steel wire or fabric reinforced rubber hoses and hose assemblies for dredging engineering and the technical requirements of GB/T 10541 - 2013 Rubber hoses for suction and discharge of oil in offshore berthing. At the same time, the above bottleneck problems have been solved.

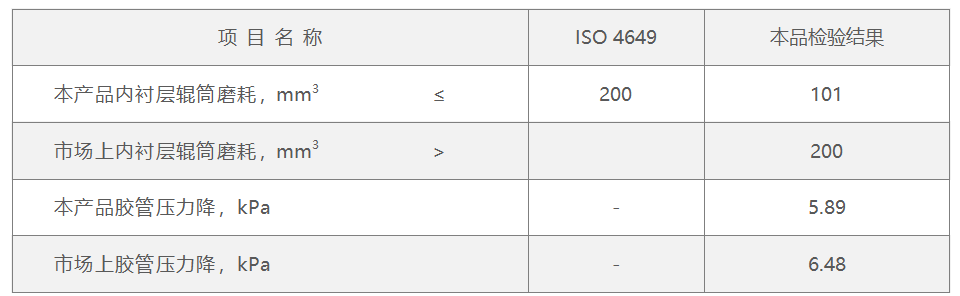

Technical indicators of wear and conveying resistance

|

|

| |