News

more+- Professor Chen Erfan, a leader of our company, was invited to attend the inauguration ceremony for the new location of Shenyang Zhilang Technology Co., Ltd. and visited its research achievements and new products.

- The 4th Annual Meeting of the Special Committee and the 3rd New Materials Science & Technology Conference Held in Hangzhou

- Professor Chen, a leader of our company, participated in the Standardization Technical Committee of the Chemical Industry and Engineering Society of China.

- Warm Congratulations on Our Company Being Awarded the Certificate of High-Tech Enterprise!

- Chairman Chen Erfan Participated in Liaoning International Rubber Technology Exchange Festival as a Specially Invited Expert.

contact

more+Contact Phone:13147811246 13147811216

Landline:13147811246 13147811216

Corporate Email:tech@rdpmcn.com

Address:Hongfa International, Shenliao Road, Tiexi District, Shenyang City, Liaoning Province, P.R.China

Sales Phone:13147811246 13147811216

Special Rubber for Cutter Disc Seat and Screw Pump Stator

Release Date:2026-01-13

Page Views:67

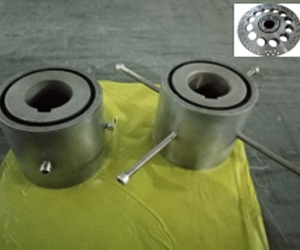

l Special rubber for cutter head seat

The cutter head seat is a key and easily worn - out component of large - scale underwater pelletizing units, and its performance depends on the rubber of the cutter head seat. Located between the rotating disk and the rotating shaft, it plays the roles of compensation and sealing. Its quality directly affects the function and quality of the underwater pelletizer. It is required to have good adhesion to the contacting components and be able to withstand a large torque. During the pelletizing process, it allows the cutter head to have a certain offset along with the die plate for pelletizing, achieving end - face swing compensation. It can compensate in any direction, enabling the cutter to fit evenly with the die plate, improving the pelletizing quality, and at the same time, extending the service life of the cutter and the die plate.

In China, most of the extrusion pelletizing units are imported from companies such as WP in Germany, Japan Steel Works (JSW), Kobe Steel in Japan, and Farrel in the United States. The domestic market has long been monopolized by foreign manufacturers. In recent years, domestic enterprises have developed and produced various specifications and models of large - scale extrusion pelletizing units for polypropylene and polyethylene. However, they still cannot meet the quality requirements, and the bottleneck problem is the inability to achieve compensation in any direction. As a result, the cutter head seat has to be imported as a complete set, causing a significant increase in costs.

Our company has specifically developed special rubber for the cutter head seat for a certain enterprise. This product can fully compete with foreign counterparts, and its service life is greatly extended.

|

|

|

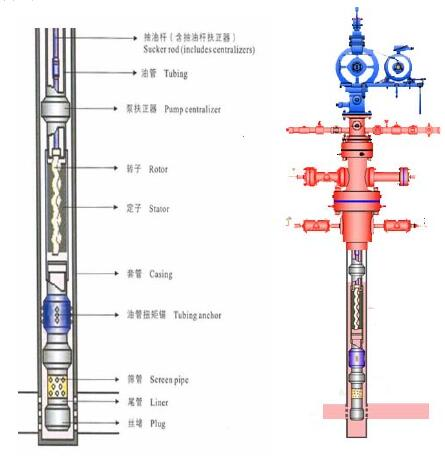

l  Special rubber for screw pump stators

Special rubber for screw pump stators

| Submersible screw pumps are new - type lifting equipment in oilfields. They possess excellent features such as high efficiency, energy conservation and environmental protection, and are widely applied in the transportation of high - viscosity media, oil - gas mixed transportation, downhole drilling and production operations, etc. The screw pump is a moving component. Its working environment is harsh and complex, with high temperature and high pressure. It rolls and slides on the surface of the rubber stator. Under long - term operation and the effect of fatigue loads, it is highly likely to cause the aging and failure of the rubber, severely shortening the service life of the screw pump. Therefore, the stator rubber is required to have good oil resistance, abrasion resistance, tear resistance, fatigue resistance and aging resistance. |  |

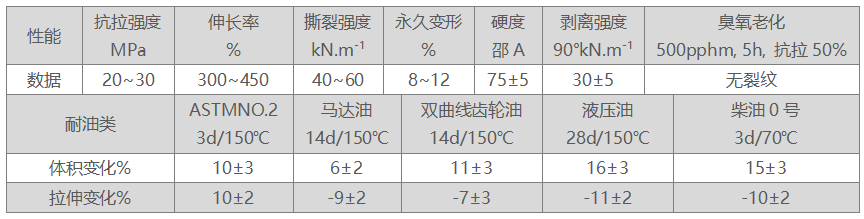

Our company has developed a series of rubber compounds that can be used for a long time at 150°C. These compounds have excellent resistance to media, high mechanical strength, as well as good ozone resistance, wear resistance, and superior dynamic performance across a wide temperature range. They are particularly suitable for various high - temperature, high - pressure, oil - resistant, and complex and harsh environments faced by the oilfield sector.

Technical characteristics