News

more+- Professor Chen Erfan, a leader of our company, was invited to attend the inauguration ceremony for the new location of Shenyang Zhilang Technology Co., Ltd. and visited its research achievements and new products.

- The 4th Annual Meeting of the Special Committee and the 3rd New Materials Science & Technology Conference Held in Hangzhou

- Professor Chen, a leader of our company, participated in the Standardization Technical Committee of the Chemical Industry and Engineering Society of China.

- Warm Congratulations on Our Company Being Awarded the Certificate of High-Tech Enterprise!

- Chairman Chen Erfan Participated in Liaoning International Rubber Technology Exchange Festival as a Specially Invited Expert.

contact

more+Contact Phone:13147811246 13147811216

Landline:13147811246 13147811216

Corporate Email:tech@rdpmcn.com

Address:Hongfa International, Shenliao Road, Tiexi District, Shenyang City, Liaoning Province, P.R.China

Sales Phone:13147811246 13147811216

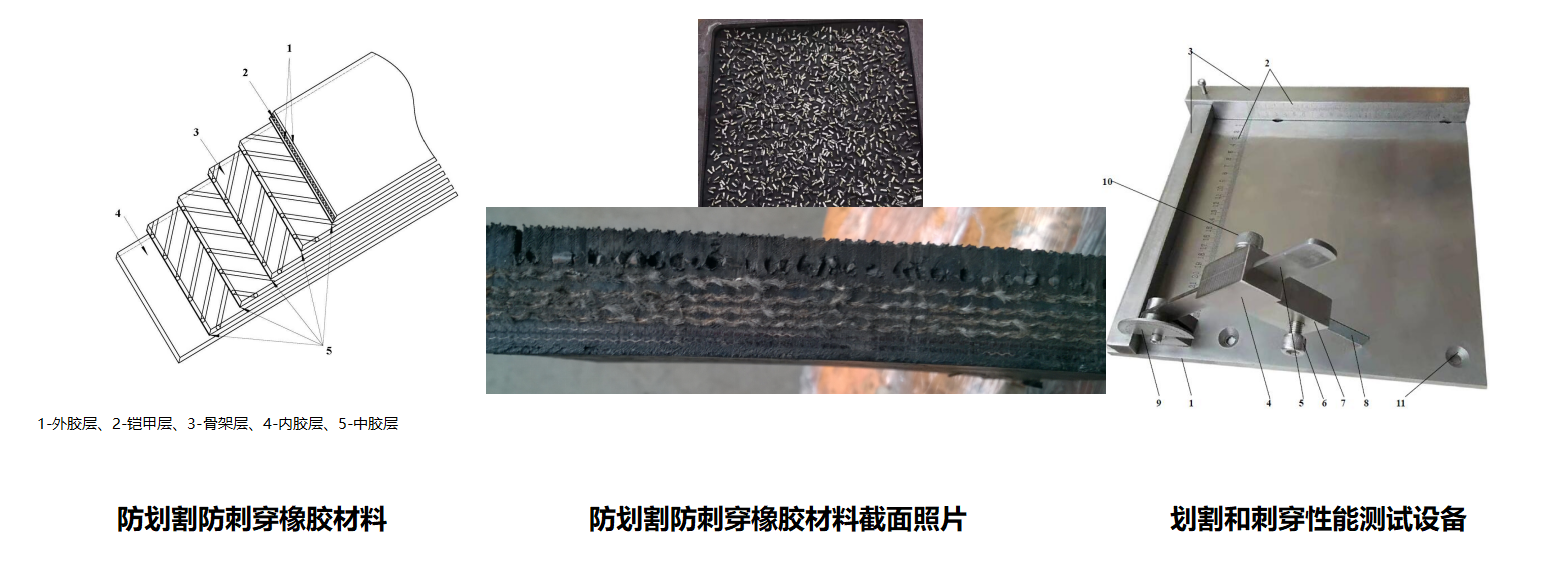

Anti-Cutting and Stable-Proof Rubber Materials & Products

Release Date:2026-01-13

Page Views:92

Rubber products are highly susceptible to damage from sharp, angular objects. For example, garbage, branches, tree roots, stone debris, ironware, glass, porcelain pieces, etc. can all cause abrasion, scratches, and punctures to rubber, especially in a water - containing environment. Such problems are widespread in rubber products and can have serious consequences, affecting items such as tires, hoses, rubber shoes, conveyor belts, rubber sheets, rubber fenders, and various rubber airbags/bags.

Our company has invented a cut - resistant and puncture - resistant rubber material, which is applied to various rubber products prone to cutting and puncturing. We have also invented a device capable of simultaneously testing cutting and puncture performance, and formulated one technical standard.

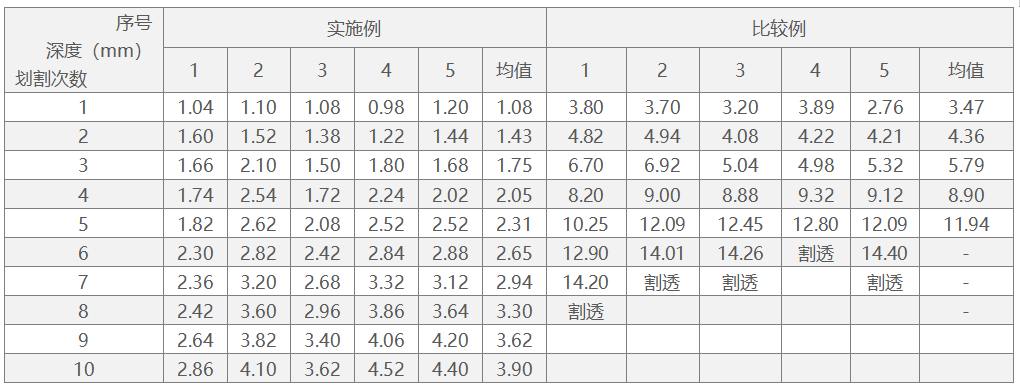

ExperimentTwo types of 19 - mm - thick rubber materials with four layers of fabric and five layers of rubber (the material of this invention and the same non - armored material) were tested for comparison.

The results show that at the same position, the cut - resistant and puncture - resistant rubber material (example of implementation) did not have its outer rubber layer (5 mm) cut or punctured. In contrast, the comparative material had its outer rubber layer penetrated after 2 - 3 cuts or punctures, and the blank sample was cut or punctured after 6 - 8 times.

Test results of cut - resistance and puncture - resistance of samples in the implementation example and the comparative example

Note: The data from 1 to 5 in the table are the average values of the warp and weft directions.