News

more+- Professor Chen Erfan, a leader of our company, was invited to attend the inauguration ceremony for the new location of Shenyang Zhilang Technology Co., Ltd. and visited its research achievements and new products.

- The 4th Annual Meeting of the Special Committee and the 3rd New Materials Science & Technology Conference Held in Hangzhou

- Professor Chen, a leader of our company, participated in the Standardization Technical Committee of the Chemical Industry and Engineering Society of China.

- Warm Congratulations on Our Company Being Awarded the Certificate of High-Tech Enterprise!

- Chairman Chen Erfan Participated in Liaoning International Rubber Technology Exchange Festival as a Specially Invited Expert.

contact

more+Contact Phone:13147811246 13147811216

Landline:13147811246 13147811216

Corporate Email:tech@rdpmcn.com

Address:Hongfa International, Shenliao Road, Tiexi District, Shenyang City, Liaoning Province, P.R.China

Sales Phone:13147811246 13147811216

MAHCPE Production Tech-Rubber type CPE

Release Date:2026-01-13

Page Views:206

English Translation

Chlorinated polyethylene is a polymer compound produced by the chlorination substitution reaction of polyethylene. It can be regarded as a terpolymer composed of ethylene, vinyl chloride, and 1,2-dichloroethylene. It is divided into two major categories: chlorinated polyethylene (CPE) and chlorinated polyethylene rubber (CM). The former is a plastic modifier, mainly used for flame retardant or toughening modification of plastics such as PVC and ABS; the latter is an elastomer, mostly used as rubber or blended with other rubbers, and is one of the most promising rubber types among halogen-containing rubbers.

Due to its highly saturated structure and chlorine content, it exhibits a series of excellent properties including weather resistance, ozone resistance, chemical resistance, heat resistance, oil resistance and flame retardancy, at a low cost. It has promising applications in automotive parts, acid-resistant hoses, oil-resistant hoses, wires and cables, sponges, seals, flame-retardant conveyor belts, V-belts and other products.

However, various problems still exist in its large-scale application:

① Poor vulcanization behavior and short plateau period;② Severe thermal brittleness during peroxide vulcanization, which easily causes tearing of products during demolding;③ Occasional bubbles or mold sticking during vulcanization, making demolding difficult;④ Ordinary oil resistance of vulcanizates, similar only to neoprene (CR), lower than nitrile rubber (NBR), and particularly poor resistance to gasoline containing alcohols;⑤ Poor low-temperature resistance of vulcanizates and high brittle temperature;⑥ Most additives used in its thermal stabilization system are environmentally harmful substances (e.g., lead salts);⑦ High hardness of vulcanizates, insufficient flexibility, and tendency to exhibit a leather-like state;⑧ Poor compatibility with other rubbers.

The bottlenecks are weak polarity and poor self-adhesion. In particular, plastic-modified CPE shows unsatisfactory performance when used as a rubber material. It is necessary to destroy the residual crystallinity of CPE and compensate for the uneven distribution of chlorine atoms on the CPE backbone.

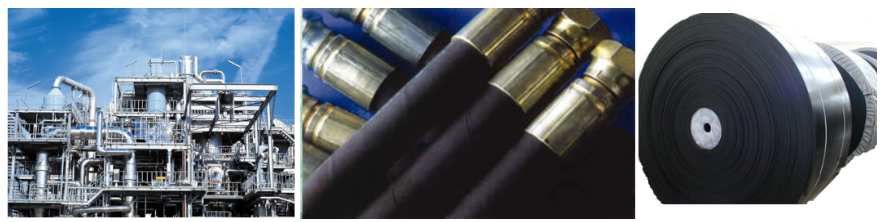

Our company has invented a suspension graft modification process for the production of CPE, and developed rubber-type MAHCPE. It has been applied in acid-resistant hoses and oil-resistant hoses, and the product performance fully meets or exceeds the requirements of national standards (GB/T 3683.1 and GB 21352).

It can meet the requirements of general rubber products (replacing NR, CR, CSM, NBR, ACM and other rubbers), and a series of products have been formed: rubber hoses and assemblies, 1kV wire and cable compounds, conveyor belts, polymer waterproof sheets and other rubber products.

| ||

| MAHCPE Production Plant | CM Hose Assembly Products | CM Rubber Sheet Products |