News

more+- Professor Chen Erfan, a leader of our company, was invited to attend the inauguration ceremony for the new location of Shenyang Zhilang Technology Co., Ltd. and visited its research achievements and new products.

- The 4th Annual Meeting of the Special Committee and the 3rd New Materials Science & Technology Conference Held in Hangzhou

- Professor Chen, a leader of our company, participated in the Standardization Technical Committee of the Chemical Industry and Engineering Society of China.

- Warm Congratulations on Our Company Being Awarded the Certificate of High-Tech Enterprise!

- Chairman Chen Erfan Participated in Liaoning International Rubber Technology Exchange Festival as a Specially Invited Expert.

contact

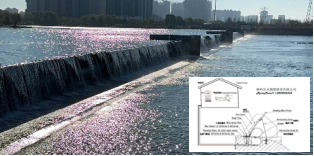

more+PSRD (3.5M*408M)

PSRD Features

Aging resistance, service life exceeding 50 years;

High pressure resistance greater than 1.2 MPa;

Puncture resistance and scratch resistance;

“Green”: Food hygiene technical indicators are 4 orders of magnitude better than national standards; no oil leakage or mechanical impurities, no pollution to water bodies and surrounding environment;

Manual, automatic and remote water level control; continuously adjustable with gradual flow acceleration, less prone to cavitation, scouring and vortices. Especially in case of power failure caused by floods, water level can still be reliably controlled by air discharge for safe flood discharge. After flood discharge, the system can operate normally even with sediment and debris deposited on the gate; low power consumption;

Simple structure and low cost; modular structure simplifies installation, operation and maintenance;

The curved gate body effectively facilitates the passage of water flow, ice blocks, gravel, branches and other debris, and protects the rubber dam body. The stiffeners on the gate also serve as flow deflectors to smooth flow and reduce scouring;

Capable of self-deicing in winter;

The steel plate is supported by an inflatable bag with the same length as the plate, requiring only a simple foundation. Construction can be carried out on existing foundations, suitable for dam heightening;

Composed of connected steel plates and dam bags with unlimited length; no intermediate piers, maintaining the clear width of the river channel; saves hoisting equipment and corresponding civil structures;

Accurate automatic water level control even without power supply (especially suitable for hydropower generation), high safety;

Stronger seismic performance. The shield plate is flexibly connected to the foundation, avoiding system failure and loss of normal operation capacity caused by foundation deformation;

Unattended operation, low management and operation cost;

Integrates ecological regulation, aesthetics, flood control and power generation functions.

Applications

Water Storage: PSRD can increase river water storage in dry / low-flow seasons, forming segmented "reservoirs" with significant ecological benefits. It effectively coordinates the water regulation capacity of spillways with reservoir water levels, boosting the storage of existing reservoirs. It reduces policy and financial difficulties (e.g., inundation issues) associated with increased water storage. When the discharge capacity of existing spillways is insufficient, this dam/gate type maintains the weir crest elevation without affecting reservoir water levels and power generation benefits.

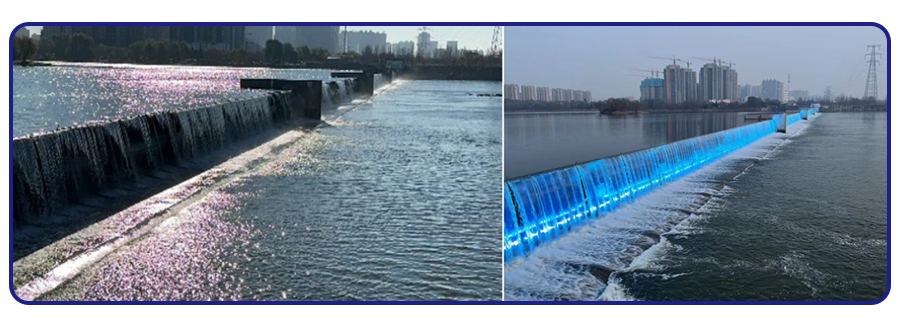

Landscape: Overflow at the dam crest forms waterfalls. Landscape lights and audio systems can be installed on the PSRD to create attractive night views and a pleasant environment.

Irrigation: Enables accurate control of water levels and diversion flows in irrigation canals. When canal flow varies, it automatically maintains the water level upstream of diversion structures, ensuring uniform water distribution.

Flow Diversion & Flood Discharge: Applicable to river flood diversion with automatic flow regulation. During flood periods, it automatically maintains a low upstream water level to allow floodwater to carry away deposited sediment, or fully collapses to preserve the original river discharge capacity.

Power Generation: Creates high water levels to enhance the power generation capacity of hydropower stations. Conventional sluice gates typically allow only 0.25–0.5 m of water depth over the crest, while PSRD can generate a higher water head and accurately control upstream water levels, safely discharging floods during wet seasons and raising to retain water afterward. Additionally, a stable ice cover can form upstream in winter, preventing ice jams at power station intakes.

Fish Passage & Environmental Protection: A series of PSRDs can form stepped fish passages to regulate flow and velocity for smooth fish migration. Controlling the upstream water level prevents sudden inundation of waterfowl habitats in reservoir areas, and stable water levels improve safety and the natural landscape.

Road & Garage Protection: PSRD can be installed at entrances of garages, subways, and underground facilities to prevent stormwater and flood intrusion. It can also be placed at gaps in flood dikes for immediate closure during floods.

Navigation: PSRD is an ideal upstream and downstream gate for ship locks, enabling accurate control of water levels. When collapsed, the steel plates lie over the rubber airbags, ensuring unobstructed vessel passage. It eliminates complex gate hoisting systems, offers flexible and simple operation, and reduces lock construction and maintenance costs.

Structural Introduction

1. Dam Body

Outer rubber: Ethylene Propylene Diene Monomer (EPDM) with excellent weather resistance;

Middle rubber: chloroprene rubber and natural rubber blend (CR+NR) with good bonding performance;

Inner rubber: modified butyl rubber with excellent air tightness.

2. Anchors

3. Pneumatic System

4. Automatic Control System and Pipelines

The automatic control system shall include: PLC, lightning protection equipment, SCADA and/or radar hydrological monitoring.The material, dimensions, specifications and shape of pipelines shall meet engineering and design requirements.

Our company provides design, construction and installation services.

内容 | 传统橡胶坝 | 钢坝闸 | RiverMate® |

耐压 | 0.02MPa | - | 1.2MPa |

使用寿命 | <15ys | 30ys | >50ys |

食品卫生 | 二次水污染 | 油泄露 | 无污染 |

水利功能 | 挡水 | 防洪抗洪 | 防洪抗洪 |

生态 | 有影响 | 有影响 | 友好 |

安装周期 | 10-20天 | 20-30天 | 7-15天 |

制造工艺 | 胶布热合机粘接(平板硫化机) | 机加 | 整体成型及巨型硫化罐生产 |

安装运行管理 | 较难,需较多人力 | 较难,需大型提升设备和精细组装 | 容易,仅需5吨车吊 |

故障 | 易刺伤及滑伤,整体工程瘫痪 | 电动、液压、机械传动不同步 | 几乎无故障 |

防洪及电力中断 | 放气时间长,影响泻洪峰 | 严重后果 | 手动,无任何影响 |

Shenyang PSRD Project (3.5 m in height × 408 m in length)

PSRD control room & PLC+SCADA control cabinet interior Schematic Diagram of PSRD