de/anti icing devices

Release Date:2026-01-13

Page Views:261

Anti-icing facilities are critical safeguards for water-retaining, discharge, conveyance and utilization structures such as dams, dikes in rivers, lakes, seas and reservoirs.By 2011, China had 157.68 million water conservancy facilities of various scales, with a total dike length of 413,679 km.Ice damage is a common occurrence to water conservancy facilities in cold regions and winter, causing varying degrees of impact or even damage, leading to accidents and huge repair costs.Ice damage has become a major issue seriously affecting the safety of water projects and people’s lives and property. In recent years, increasing attention has been paid to the research on anti-icing and freeze-proof technologies.

At present, there are five main measures against ice damage:

Manual method;

Mechanical method;

Electric heating melting method;

Water flow disturbance method, which features small jet range, high energy consumption, poor stability and easy damage to water conservancy facilities;

Bubble method, which achieves fast ice breaking but with low efficiency and high cost.

Related research in China is relatively limited, with the water flow disturbance method and bubble method as the main applications.

Since 2018, our company has invested a large amount of manpower, capital and resources in R&D, carrying out effective work covering overall design, materials, structure, technology, tooling and equipment. The total development investment has reached more than 3 million yuan, equivalent to 20 person‑years of scientific research.The new‑generation anti-icing equipment developed has been successfully installed and applied in more than 10 water conservancy facilities.Achievements include 1 invention patent, 1 utility model patent, 2 software copyrights and 1 technical standard.

The anti-icing mechanism of gas‑liquid bubbles generated by the dedicated aerator is based on the rising behavior of bubbles in water, including factors such as bubble shape, size, rising velocity, drag force, supercooled water formation and entrained water volume.

Through systematic and in‑depth research on the anti‑icing mechanism of the gas (liquid) bubble method, combined with actual engineering conditions and requirements, our company has proposed for the first time the control concept of micro gas‑liquid bubble anti‑icing and de‑icing equipment.

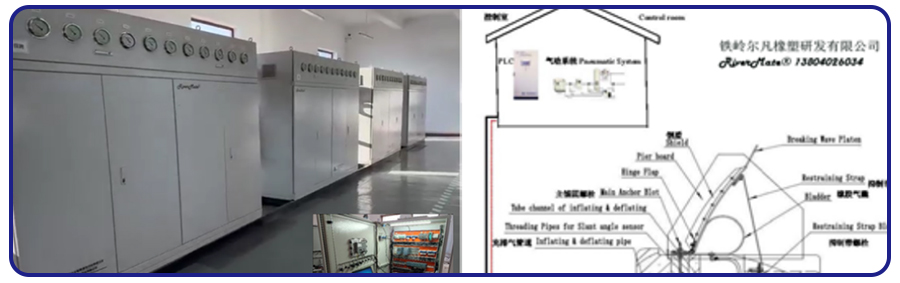

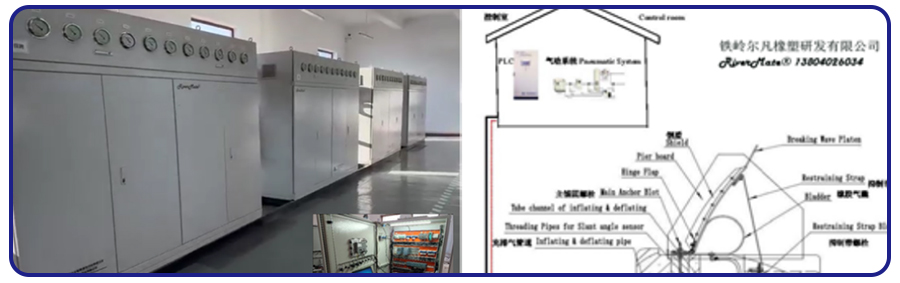

The complete equipment consists of three parts:

1Air supply system and pipelines;

2Aeration components;

3Control system.

The control system acts as the brain, the aeration components as the functional body, and the air supply system and pipelines as the resource supplier.

The control system comprises three subsystems:

1Automatic control system (PLC);

2Remote data acquisition and supervisory control system (SCADA);

3Manual mechanical centralized control manifold (valve assembly, confluence bus).

Through monitoring of various operating conditions via sensors (temperature, water pressure / depth, air supply pressure / flow, solenoid valves, as well as operating status of functional equipment and components), the control system intelligently generates gas‑liquid bubbles.Human‑machine coordination is realized to meet anti‑icing performance and requirements.

Technical and Device Features

1)Applicability: The micro gas-liquid bubble anti-icing equipment and method are suitable for application at a vertical depth of up to 6 meters below the water surface and an ambient temperature not lower than -45 °C (the thickest ice layer in China is 300–800 mm).

2)Materials: The polymer diaphragm used in the micro gas-liquid bubble aerator has the following properties: hardness (Shore A) 55–65, low-temperature brittleness -50 °C, tensile strength ≥ 20 MPa, elongation at break 50%, tear strength 38 kN/m, flex resistance 10,000 cycles. Water aging resistance (70 °C × 96 h): volume change rate ≤ 5%, tensile strength 18 MPa. The material is acid and alkali resistant, weather resistant, with a service life exceeding 50 years.

3)Key Components: The polymer diaphragm of the micro gas-liquid bubble aerator has a burst pressure greater than 0.8 MPa, operating pressure resistance of 0.1 MPa, and aeration pore diameter of 60–100 μm with free opening and closing. The micro air jets form a 45° angle with the slightly curved rubber diaphragm, and the micro holes are arranged in a triangular pattern from top to bottom. The service life of the aerator is 30 years.

4)Intelligence: Manual, automatic and remote gas supply and control of micro gas-liquid bubbles, with equipment/components and system configuration supporting 0.01-second real-time response. The automatic control system (PLC), remote monitoring system (SCADA), as well as sensing, decision-making, control, actuation, human-machine interaction and automatic alarm functions all achieve 0.01-second real-time performance. The system can operate automatically under -50 °C to 60 °C conditions and realizes unattended operation. Data transmission via 5G supports mobile APP monitoring and control, and integration into the smart water conservancy monitoring platform.

5)Product Universality: It is planned to develop products for various working conditions, which can be installed underwater or suspended/lifted. They meet the anti-icing requirements of water-retaining, discharge, conveyance and utilization structures such as dams and dikes in rivers, lakes, seas, reservoirs and other water environments. According to different energy consumption requirements, the air supply system is designed in three types: heat recovery energy-saving type, permanent magnet variable-frequency energy-saving type, and fixed-frequency high-efficiency type.

Photos of De-icing & Anti-icing Performance (Shenyang, -25℃) Schematic Diagram of Anti-Icing & De-Icing System